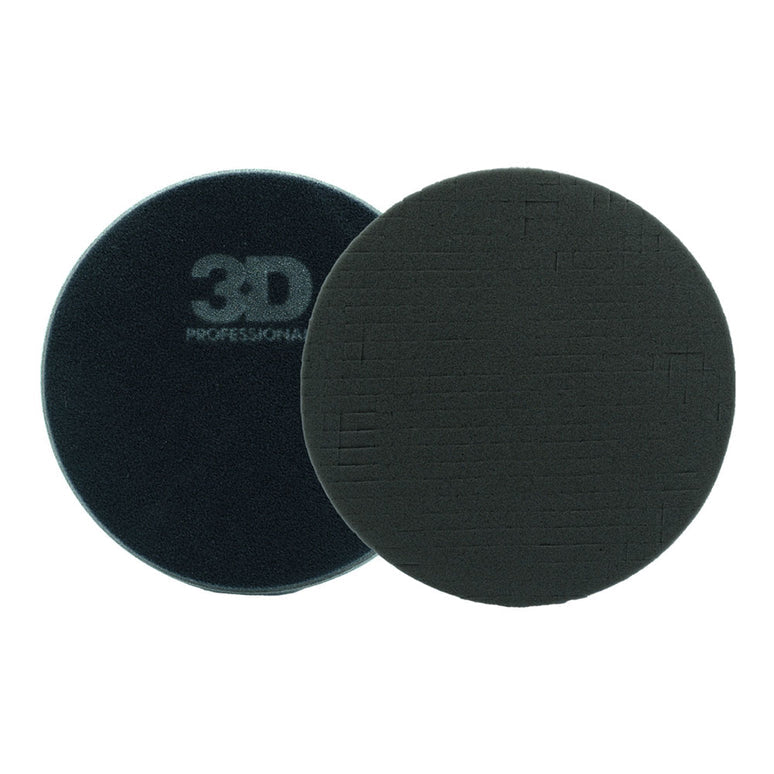

3D Black Spider-Cut Foam Finishing Pad

Maximize gloss and clarity with 3D’s spider-cut design foam pads

Some people think foam is foam, but this is simply not true. There’s a lot of chemistry and physics that go into the design of a quality foam pad. 3D’s quality foam buffing pads use the latest in foam chemistry to create pads that simply outperform the competition.

Note: 5.5" Pad does NOT have criss-cross cuts, it's a NON-Spider pad.

Foam Chemistry

Different chemicals can be added to a foam formula to make foam react differently under time, heat, and pressure and exposure to liquids or chemicals. Simple, non-descript foam pads cost less and that’s because they do less. Cheap pads also don’t last as long.

Unique foam structure

Run your hand over the face of a clean, dry 3D black spider-cut finishing pad and you’ll feel a super soft, plush foam surface. This pad is for doing final polishing work after more aggressive compounding and polishing steps. The soft foam texture provides little to no cut depending upon the product and paint.

Pad design

The slotted spider-cuts across the face of our foam finishing pad flex when spinning against the surface, this increases their surface area, which increases their finishing ability for faster refining of the surface and finishing swirl-free and show car quality.

Product trapping

The spider-cut structure flexes to open up when buffing allowing the polish powders or abrasives to migrate in-between the spider-cuts trapping them in the pad for extended work time and more efficient finishing and refining of the surface. As you’re buffing, the abrasives have greater contact against the surface for a more efficient finishing-effect.

Longer lasting

The open-cell design also offers great tensile strength as compared to closed-cell foam pads and this means they are more tear-resistant and thus last longer.

Cooler buffing temperatures

The slotted spider-cuts across the face of the pad flex as you buff allowing better air movement over and through the pad for improved heat transfer from the pad to the air. This helps keep surface temperatures lower and helps to prevent the face of the pad from bowling-in.

Excellent finishing range

3D’s black spider-cut finishing pads are versatile because they offer very light polishing to very fine finishing simply by changing the product. To get light cutting or the ultimate flawless finish, use with 3D’s 502, 520, ONE or SPEED.

Best value

These pads offer a great range of polishing options, and the foam is extra durable. 3D’s buffing pads don’t cost more money, they make you more money.

Versatile

Our black spider-cut finishing pads work great on any type of polisher including rotary polishers, long stroke polishers, short stroke polishers, free spinning polishers, and gear-driven polishers.

What is it?

High performance super soft foam finishing pad for use with rotary and orbital polishers.

What does it do?

When used with 3D polishes and AIOs, these foam finishing pads will refine the results from the previous step while maximizing gloss and clarity.

When do you use it?

Typically foam finishing pads are used when you want to create the most perfect, mirror-like finish. When doing multiple step paint correction, a finishing pad is used for the last step after more aggressive steps like compounding and polishing. Depending upon your expectations for final finish quality, the finishing step can be an optional step if the polishing step created the results you were looking for and expecting.

Why use 3D’s Black Spider-Cut Finishing pads over other options?

All the foam used to create 3D’s foam pads is of the highest quality. Cheap foam buffing pads don’t last long because the foam tears-up or bowls inward when exposed to high temperatures from heavy compounding.